RBMK Reactors – Appendix to Nuclear Power Reactors

- The RBMK is an unusual reactor design, one of two to emerge in the Soviet Union in the 1970s.

- The design had several shortcomings, and was the design involved in the 1986 Chernobyl disaster.

- Major modifications have been made to the RBMK reactors still operating.

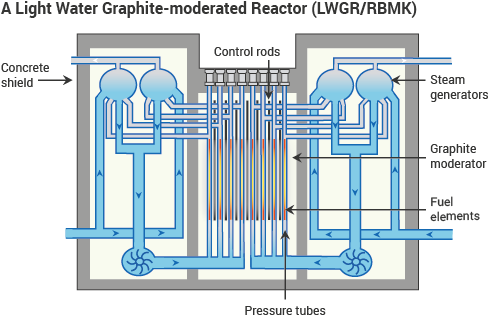

The Soviet-designed RBMK (reaktor bolshoy moshchnosty kanalny, high-power channel reactor) is a water-cooled reactor with individual fuel channels and using graphite as its moderator. It is also known as the light water graphite reactor (LWGR). As with a boiling water reactor (BWR), water boils in the fuel channels (at about 6.9 MPa) and steam is separated above them in a single circuit. It was designed over 1964-66 and is very different from most other power reactors. Its precursors were an experimental 30 MWt (5 MWe) LWGR at Obninsk which started up in 1954, and two small prototype LWGR (AMB-100 & 200) units – Beloyarsk 1&2, which ran from 1964 and 1968 respectively. (The ADE reactors at Zheleznogorsk and Seversk used for plutonium production are similar to the RBMK but with much lower power density and smaller fuel elements.)

The combination of graphite moderator and water coolant is found in no other power reactors in the world. As the Chernobyl accident showed, several of the RBMK's design characteristics – in particular, the control rod design and a positive void coefficient – were unsafe. A number of significant design changes were made after the Chernobyl accident to address these problems.

Features of the RBMK

Fuel

Pellets of slightly-enriched uranium oxide are enclosed in a zircaloy tube 3.65m long, forming a fuel rod. A set of 18 fuel rods is arranged cylindrically in a carriage to form a fuel assembly. Two of these end on end occupy each pressure tube.

Pressure tubes

Within the reactor each fuel assembly is positioned in its own vertical pressure tube or channel about 7 m long. Each channel is individually cooled by pressurised water which is allowed to boil in the tube and emerges at about 290°C.

Refuelling

When fuel channels are isolated, the fuel assemblies can be lifted into and out of the reactor, allowing fuel replenishment while the reactor is in operation.

Graphite moderator

A series of graphite blocks surround, and hence separate, the pressure tubes. They act as a moderator to slow down the neutrons released during fission so that a continuous fission chain reaction can be maintained. Heat conduction between the blocks is enhanced by a mixture of helium and nitrogen gas.

Control rods

Boron carbide control rods absorb neutrons to control the rate of fission. A few short rods, inserted upwards from the bottom of the core, even the distribution of power across the reactor. The main control rods are inserted from the top down and provide automatic, manual, or emergency control. The automatic rods are regulated by feedback from in-core detectors. If there is a deviation from normal operating parameters (e.g. increased reactor power level), the rods can be dropped into the core to reduce or stop reactor activity. A number of rods remain in the core during operation.

Coolant

Two separate water coolant loops each with four pumps circulate water through the pressure tubes to remove most of the heat from fission. There is also an emergency core cooling system which is designed to come into operation if either coolant circuit is interrupted.

Steam separator

Each of the two loops has two steam drums, or separators, where steam from the heated coolant is fed to the turbine to produce electricity in the generator (each loop has a turbogenerator associated with it). The steam is then condensed and fed back into the circulating coolant.

Containment

There is no secure containment in the sense accepted in the West. The reactor core is located in a reinforced concrete lined cavity that acts as a radiation shield. The core sits on a heavy steel plate, with a 1000 tonne steel cover plate on the top. The extensions of the fuel channels penetrate the lower plate and the cover plate and are welded to each. The steam separators of the coolant systems are housed in their own concrete shields.

Positive void coefficient

The term 'positive void coefficient' is often associated with RBMK reactors.

Reactors cooled by boiling water will contain a certain amount of steam in the core. Because water is both a more efficient coolant and a more effective neutron absorber than steam, a change in the proportion of steam bubbles, or 'voids', in the coolant will result in a change in core reactivity. The ratio of these changes is termed the void coefficient of reactivity. When the void coefficient is negative, an increase in steam will lead to a decrease in reactivity.

In those reactors where the same water circuit acts as both moderator and coolant, excess steam generation reduces the slowing of neutrons necessary to sustain the nuclear chain reaction. This leads to a reduction in power, and is a basic safety feature of most Western reactors.

In reactor designs where the moderator and coolant are of different materials, excess steam reduces the cooling of the reactor, but as the moderator remains intact the nuclear chain reaction continues. In some of these reactors, most notably the RBMK, the neutron absorbing properties of the cooling water are a significant factor in the operating characteristics. In such cases, the reduction in neutron absorption as a result of steam production, and the consequent presence of extra free neutrons, enhances the chain reaction. This leads to an increase in the reactivity of the system.

The void coefficient is only one contributor to the overall power coefficient of reactivity, but in RBMK reactors it is the dominant component, reflecting a high degree of dependence of reactivity on the steam content of the core. At the time of the accident at Chernobyl, the void coefficient of reactivity was so positive that it overwhelmed the other components of the power coefficient, and the power coefficient itself became positive. When the power began to increase, more steam was produced, which in turn led to an increase in power. The additional heat resulting from the increase in power raised the temperature in the cooling circuit and more steam was produced. More steam means less cooling and less neutron absorption, resulting in a rapid increase in power to around 100 times the reactor's rated capacity.

The value of the void coefficient is largely determined by the configuration of the reactor core. In RBMK reactors, an important factor affecting this is the operating reactivity margin.

Operating reactivity margin

Although the definition is not precise, the operating reactivity margin (ORM) is essentially the number of 'equivalent' control rods of nominal worth remaining in the reactor core. The operators at Chernobyl seemed to believe that safety criteria would be met so long as the lower limit for the ORM of 15 equivalent rods was adhered to, regardless of the actual configuration of the core. The operators were not aware of the 'positive scram' effect where, following a scram signal, the initial entry of the control rods actually added reactivity to the lower region of the core (see section below on Post accident changes to the RBMK).

The ORM could have an extreme effect on the void coefficient of reactivity, as was the case for the core configuration of Chernobyl 4 in the run-up to the accident. Unacceptably large void coefficients were prevented for initial cores by increasing fuel enrichment levels, with the excess reactivity balanced by fixed absorbers. However, with increasing fuel burn-up, these absorbers could be removed to maintain the fuel irradiation levels - shifting the void coefficient in the positive direction and increasing the sensitivity of the coefficient to the extent of insertion of the control and protection rods.

Post accident changes to the RBMK

After the accident at Chernobyl, several measures were taken to improve the safety of RBMK plants. All operating RBMK reactors in the former Soviet Union had the following changes implemented to improve operating safety:

- Reduction of the void coefficient of reactivity.

- Improvement of the response efficiency of the emergency protection system.

- Introduction of calculation programs to provide an indication of the value of the operating reactivity margin (ORM, i.e. the effective number of control rods remaining in the core) in the control room.

- Prevention of the emergency safety systems from being bypassed while the reactor is operating.

- In order to ensure adequate subcooling at the core inlet, the avoidance of modes of operation that cause a reduction in the departure from nucleate boiling (DNB) ratio of the coolant at the reactor inlet.

Measures to reduce the void coefficient of reactivity were carried out by:

- The installation of 80-90 additional fixed absorbers in the core to inhibit operation at low power.

- Increasing the ORM from 26-30 rods (in steady state operational mode) to 43-48.

- An increase in fuel enrichment from 2% to 2.4%.

The increase in the number of fixed absorbers and the ORM reduced the value of the void coefficient of reactivity to +ß (where ß is the effective delayed neutron fraction). The additional absorbers require the use of higher fuel enrichment to compensate for the increased neutron absorption.

The efficiency and speed of the emergency protection system was improved by implementing three independent retrofitting operations:

- Retrofitting of control rods with a design that does not give rise to water columns at the bottom of the channels.

- Scram (shut down) rod insertion time cut from 18 to 12 seconds.

- The installation of a fast-acting emergency protection (FAEP) system.

One of the most important post-accident changes to the RBMK was the retrofitting of the control rods. A graphite 'displacer' is attached to each end of the length of absorber of each rod (except for 12 rods used in automatic control). The lower displacer prevents coolant water from entering the space vacated as the rod is withdrawn, thus augmenting the reactivity worth of the rod. However, the dimensions of the rod and displacers were such that, with the rod fully withdrawn, the 4.5 m displacer sat centrally within the fuelled region of the core with 1.25 m of water at either end. On a scram signal, as the rod falls, the water at the lower part of the channel is replaced by the bottom of the graphite displacer, thus initially adding reactivity to the bottom part of the core. Following the Chernobyl accident, this 'positive scram' effect was mitigated by retrofitting the control rods so that, with the rods fully retracted, there would not be a region containing water at the bottom of the core.

The FAEP system was designed so that 24 emergency protection control rods would insert negative reactivity of at least 2ß in under 2.5 seconds. Tests in 1987-'88 at the Ignalina and Leningrad plants (the first RBMKs to be fitted with the new FAEP system) confirmed these characteristics.

In addition to the above changes, several further modifications have been implemented at RBMK plants. These measures consist of:

- Replacement of the fuel channels at all units (except Smolensk 3).

- Replacement of the group distribution headers and addition of check valves.

- Improvements to the emergency core cooling systems.

- Improvements of the reactor cavity over-pressure protection systems.

- Replacement of the SKALA process computer.

Operating RBMK plants

There are currently eight operating RBMKs, all of which are in Russia. One more was under construction in Russia (Kursk 5), but it is now cancelled. All operating RBMKs began operation between 1979 (Kursk 2) and 1990 (Smolensk 3). There are three distinct generations of RBMK reactors having significant differences with respect to their safety design features:

- The four first-generation units are Leningrad 1&2 (both now shutdown), and Kursk 1 (now shutdown) and 2. They were designed and brought online in the early-to-mid-1970s, before new standards on the design and construction of nuclear power plants, the OPB-82 General Safety Provisions, were introduced in the Soviet Union in 1982.

- Second-generation RBMKs, brought online since the late 1970s and early 1980s include Leningrad 3&4; Kursk 3&4; Ignalina 1 (now shutdown); and Smolensk 1&2. Ignalina 2 (now shutdown) had safety features beyond those of other second generation units. These units conform to the OPB-82 standards.

- After the Chernobyl accident, Soviet safety standards were revised again (OPB-88). One RBMK (Smolensk 3) has been built to these third-generation standards. Additional design changes were being incorporated in the construction of Kursk 5 before it was cancelled.

In 2006, Rosatom said it was considering operating lifetime extensions and uprating of its operating RBMK reactors. Following significant design modifications made after the Chernobyl accident, as well as extensive refurbishment including replacement of fuel channels, a 45-year operating lifetime is seen as realistic for the 1000 MWe-class units. In 2021, they provided about 25% of Russia's nuclear-generated electricity.

In the Table below, the 'operating until' dates are the scheduled shutdown for these plants, with 15-year lifetime extensions in some cases. Lithuania, on the other hand, closed Ignalina 1&2 early as a condition for entry into the European Union.

Russia's long-term plans had earlier included the possibility of replacing the Leningrad units, at the end of their extended service life, by new MKER-1000 units. These are a modification of the RBMK design. The main differences are in the spacing of the graphite lattice in the core and the incorporation of passive safety systems.

RBMK reactors

| Location | Unit | First power | Unit net capacity (MWe) | Status |

| Lithuania | ||||

| Ignalina | 1 | 1983 | 1185 (originally 1300) | Closed 12/2004 |

| 2 | 1987 | 1185 (originally 1300) | Closed 12/2009 | |

| Russia | ||||

| Kursk | 1 | 1976 | 925 | Closed 12/2021 |

| 2 | 1979 | 925 | Operating until 2024 | |

| 3 | 1984 | 925 | Operating until 2029 | |

| 4 | 1986 | 925 | Operating until 2031 | |

| 5 | - | Construction cancelled | ||

| Leningrad | 1 | 1973 | 925 | Closed 12/2018 |

| 2 | 1975 | 925 | Closed 11/2020 | |

| 3 | 1979 | 925 | Operating until 2025 | |

| 4 | 1981 | 925 | Operating until 2026 | |

| Smolensk | 1 | 1983 | 925 | Operating until 2028 |

| 2 | 1985 | 925 | Operating until 2030 | |

| 3 | 1990 | 925 | Operating until 2050 | |

| Ukraine | ||||

| Chernobyl | 1 | 1977 | 925 | Closed 1996 |

| 2 | 1978 | 925 | Closed 1991 | |

| 3 | 1981 | 925 | Closed 2000 | |

| 4 | 1983 | 925 | Reactor destroyed April 1986 | |

| 5 | - | 925 | Construction cancelled | |

| 6 | - | 925 | Construction cancelled | |

Operational dates are subject to licence extension – see information page on Nuclear Power in Russia.

Notes & references

General sources

INSAG-7, The Chernobyl Accident: Updating of INSAG-1, A report by the International Nuclear Safety Advisory Group, International Atomic Energy Agency, Safety Series No. 75-INSAG-7, 1992, (ISBN: 9201046928). See especially: Annex I of INSAG-7, the Report by a Commission to the USSR State Committee for the Supervision of Safety in Industry and Nuclear Power (SCSSINP); and Annex II of INSAG-7, the Report by Working Group of USSR Experts, Causes and Circumstances of the Accident at Unit 4 of the Chernobyl Nuclear Power Plant and Measures to Improve the Safety of Plants with RBMK Reactors (Moscow, 1991)

Related information

Nuclear Power ReactorsChernobyl Accident

Russia: Nuclear Power

Early Soviet Reactors and EU Accession